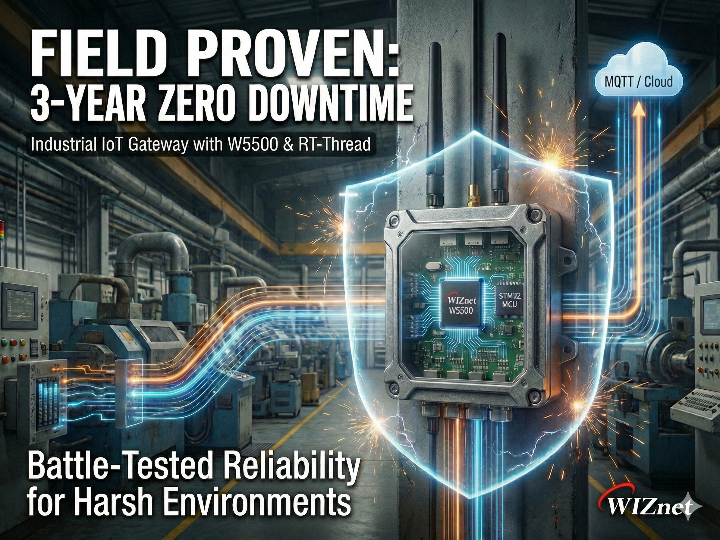

Zero Downtime for 3 Years: A Battle-Tested Industrial IoT Gateway with W5500 & RT-Thread

3-year field-proven IIoT Gateway using W5500 & RT-Thread. Zero downtime Modbus-to-MQTT solution on low-cost MCUs.

1. Introduction

The industrial field is vastly different from a development lab. Constant electromagnetic noise, unstable power supplies, and slow router response times render standard example codes useless in real-world scenarios.

This project is not just a simple functional demonstration. It is a High-Reliability IIoT (Industrial IoT) Gateway solution that combines the hardware TCP/IP acceleration of the WIZnet W5500 with the real-time scheduling of RT-Thread (RTOS). It has been successfully verified with Zero Downtime over 3 years of operation in harsh industrial environments.

2. System Architecture

This system acts as a robust bridge connecting field equipment (PLCs/Sensors) to the cloud (MQTT Broker).

Field Layer (Left): Collects PLC and sensor data via Modbus RTU.

Gateway Layer (Center): Powered by the STM32F103 + W5500 combination, handling data conversion and communication on top of an RTOS.

Cloud Layer (Right): Transmits collected data to the control server via the MQTT Protocol.

Key Point: It features a Fail-Safe Design. Even if the network disconnects (MQTT Fail), the field control logic (Modbus Loop) never stops or delays.

3. Tech Deep Dive: SW/HW Stack

The critical differentiator of this project is the integration of RT-Thread (RTOS) and the Offloading Technology of the W5500.

① RT-Thread (OS Layer)

Adopts a Multi-threaded structure instead of a single while loop.

Priority Scheduling: The Modbus processing thread is assigned higher priority, ensuring that machine control timing is never compromised, even during network latency.

② W5500 Hardwired TCP/IP (H/W Layer)

Overcoming Low-Spec MCU Limits: The MCU used (STM32F103RBT6) has only 20KB of RAM.

If a software TCP/IP stack (like LwIP) were used, the system would crash due to memory overflow. However, the W5500 offloads TCP/IP processing, allowing SSL security and the RTOS to run smoothly with ample resources remaining.

Feature | Software TCP/IP Stack | W5500 Hardware TCP/IP |

|---|---|---|

MCU Load | High (CPU handles packets) | Very Low (Chip handles packets) |

Required RAM | 50KB+ Recommended | 20KB is Sufficient (Cost Reduction) |

Reliability | Unstable during traffic spikes | Stable against traffic/attacks |

4. Battle-Tested Features (Field Expertise)

This project implements "Survival Code" refined over 3 years on the factory floor.

Dynamic Heartbeat Algorithm

It analyzes network quality (packet loss rate) in real-time. The heartbeat interval automatically adjusts (shortens to 15s for poor conditions, extends to 60s for stable conditions) to maintain connection.

Smart Reconnect Strategy

Instead of infinite loops during DHCP failure, it uses Back-off algorithms to prevent router overload while attempting to restore the connection.

EMI/EMC Hardware Protection

To protect the W5500 from surges caused by factory motor startups, TVS Diodes are applied to the reset and communication lines, ensuring hardware durability.

5. Conclusion & Future Vision

This project proves that WIZnet solutions are not just for makers but are core components for the Industrial IoT market.

Commercial Ready: Verified code and hardware design significantly reduce development time.

Cost Innovation: Achieves high-performance gateway capabilities using a low-cost MCU + W5500 combination, eliminating the need for expensive high-end MCUs.

Scalability: The current structure can easily extend to connect with AWS IoT Core or Azure IoT Hub, evolving into an Edge AI-based predictive maintenance system.

Link : https://blog.csdn.net/2504_94303751/article/details/156537997