Smart Water Treatment System Based on W5500

Smart Water Treatment System Based on W5500: Automated Control for Iron, Manganese, and H₂S Removal

Smart Water Treatment Controller with Arduino DUE & WIZnet W5500

1. Project Overview

This project introduces a next-generation water treatment controller designed for households and small facilities with challenging groundwater conditions (high iron, manganese, hydrogen sulfide, and hardness).

At its core, the system uses:

MCU: Arduino DUE Core (ARM SAM3X8E)

Ethernet: WIZnet W5500 (stable TCP/IP networking with built-in web server)

Key Sensors & Devices:

BMP-based pressure sensor (0–6 bar, 0–5V)

4–20 mA water level sensor for 500 L storage tank

Load cell + HX711 for chlorine reagent tank

Flowmeter for proportional dosing

Autotrol 263 & Runxin F68C3 filter heads

Leakage/flood sensors, temperature sensors (DS18B20)

PZEM-004T v3 for energy monitoring

The goal: combine robust automation, full sensor integration, and remote monitoring into one embedded controller.

2. How the System Works

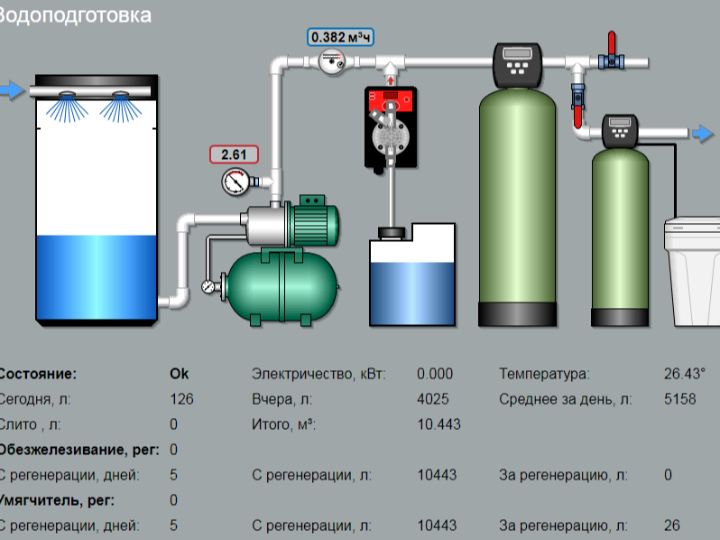

Water Flow & Treatment

Raw water → aeration tank → pump station → iron removal filter (Quantum DMI-65 + chlorine) → softener → household supply.

Chlorine Dosing

Flowmeter pulses drive proportional chlorine injection.

Tank weight monitoring ensures real-time chemical usage tracking.

Filter Backwash & Regeneration

Time-based and flow-based triggers.

Synchronization logic prevents simultaneous regeneration.

Pump Station Control

Pressure sensor + dry-run protection.

Overload detection via Modbus power meter.

Web & Local Interface

Ethernet (W5500) hosts graphical web UI with mobile support.

LCD2004 + keypad for local fallback control.

Safety & Reliability

12-hour auto-flush to prevent stagnation.

Backup float sensors for tank dry-run protection.

Leak/flood sensors trigger alarms.

3. Key Technologies

WIZnet W5500 Ethernet:

Ensures robust web interface and real-time remote monitoring.

Supports email/SMS notifications over network.

HX711 Load Cell: Monitors reagent tank weight continuously.

4–20 mA Analog Input: Provides industrial-grade tank level accuracy.

PZEM-004T v3: Power monitoring via Modbus RTU.

RTC + EEPROM: Reliable scheduling and long-term statistics logging.

4. Applications & Benefits

Applications

Household & industrial groundwater purification

Remote-managed small-scale water treatment plants

Smart home integration for water safety

Benefits

Prevents pump damage (dry-run & overload protection)

Extends filter media life with optimized regeneration cycles

Provides full visibility of system health via web dashboard

Scalable: easy to add more sensors, Modbus devices, or IoT cloud connectivity

5. Conclusion

This project demonstrates how Arduino DUE + WIZnet W5500 can evolve a traditional water purification system into a smart, connected, and resilient controller.

👉 Key takeaway:

“W5500 transforms a standalone water system into a networked, safe, and intelligent IoT solution.”