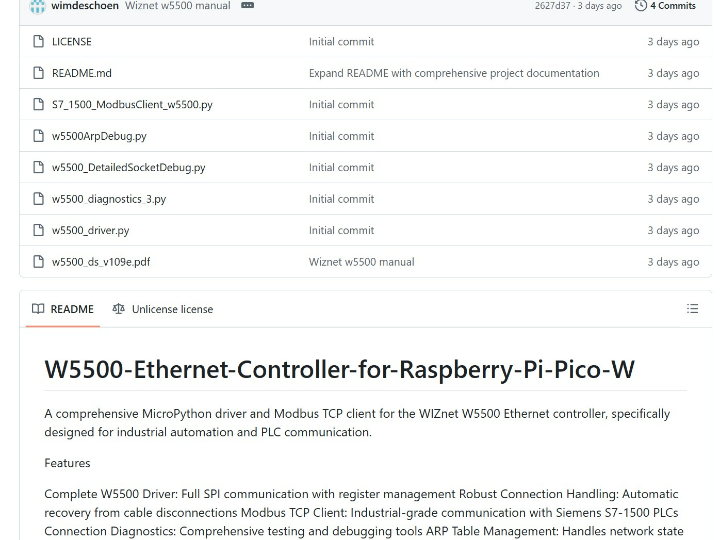

W5500-Ethernet-Controller-for-Raspberry-Pi-Pico-W

A comprehensive MicroPython driver and Modbus TCP client for the WIZnet W5500 Ethernet controller, specifically designed for industrial automation and PLC commu

A comprehensive MicroPython driver and Modbus TCP client for the WIZnet W5500 Ethernet controller, specifically designed for industrial automation and PLC communication.

Features

Complete W5500 Driver: Full SPI communication with register management Robust Connection Handling: Automatic recovery from cable disconnections Modbus TCP Client: Industrial-grade communication with Siemens S7-1500 PLCs Connection Diagnostics: Comprehensive testing and debugging tools ARP Table Management: Handles network state recovery after link interruptions

Hardware Requirements

Raspberry Pi Pico W WIZnet W5500 Ethernet Module SPI connections as specified below

Wiring W5500 PinPico PinFunctionSCKGP10SPI ClockMOSIGP11SPI Master OutMISOGP12SPI Master InCSGP13Chip SelectRSTGP15ResetVCC3V3Power SupplyGNDGNDGround Quick Start Basic W5500 Setup pythonfrom w5500_driver import W5500

w5500 = W5500(sck_pin=10, mosi_pin=11, miso_pin=12, cs_pin=13, rst_pin=15)

w5500.set_mac_address("02:08:DC:15:00:28") w5500.set_ip_address("192.168.1.100") w5500.set_subnet_mask("255.255.255.0") w5500.set_gateway("192.168.1.1")

phy = w5500.get_phy_status() print(f"Link: {'UP' if phy['link'] else 'DOWN'}") Siemens PLC Communication pythonfrom w5500_driver import W5500 from siemens_modbus_client import SiemensModbusTCP

w5500 = W5500(sck_pin=10, mosi_pin=11, miso_pin=12, cs_pin=13, rst_pin=15)

plc = SiemensModbusTCP(w5500, local_ip="192.168.123.29", plc_ip="192.168.123.10")

if plc.connect(): # Read holding registers data = plc.read_holding_registers(0, 10) print(f"PLC Data: {data}")

# Write to PLC

plc.write_single_register(100, 1234)

plc.disconnect()

File Structure ├── w5500_driver.py # Core W5500 driver ├── siemens_modbus_client.py # Modbus TCP client for Siemens PLCs ├── detailed_socket_debug.py # Socket debugging tools ├── arp_debug_script.py # ARP resolution diagnostics ├── improved_diagnostics.py # Enhanced diagnostic suite └── simple_reset_test.py # Basic connectivity tests Core Components W5500 Driver (w5500_driver.py) Key Classes:

W5500: Main driver class with SPI communication W5500ModbusTCP: Basic Modbus TCP implementation

Features:

Variable Data Mode (VDM) SPI communication Socket management (TCP/UDP) Network configuration PHY status monitoring Hardware and software reset capabilities

Siemens Modbus Client (siemens_modbus_client.py) Class: SiemensModbusTCP Supported Functions:

read_holding_registers(start, count) - Function Code 3 write_single_register(address, value) - Function Code 6 write_multiple_registers(start, values) - Function Code 16 read_input_registers(start, count) - Function Code 4

Built-in Features:

Automatic ARP table management Connection monitoring and recovery Industrial network timeouts (500ms, 10 retries) Force ARP mode for reliable connectivity

Diagnostic Tools Hardware Diagnostics python# Run comprehensive hardware tests exec(open('improved_diagnostics.py').read())

exec(open('arp_debug_script.py').read())

exec(open('simple_reset_test.py').read()) Socket Debugging python# Detailed socket state monitoring exec(open('detailed_socket_debug.py').read()) Network Configuration Examples Standard Network pythonw5500.set_ip_address("192.168.1.100") w5500.set_subnet_mask("255.255.255.0") w5500.set_gateway("192.168.1.1") Machine Network (Siemens) pythonplc = SiemensModbusTCP(w5500, local_ip="192.168.123.29", subnet="255.255.255.0", gateway="192.168.123.1") plc.set_plc_address("192.168.123.10") Troubleshooting Connection Issues After Cable Disconnect The driver includes automatic recovery mechanisms: python# Manual recovery if needed plc.reconnect()

from arp_debug_script import clear_arp_and_reset clear_arp_and_reset(w5500) Common Error Codes Status CodeDescriptionSolution0x00Socket ClosedCheck network configuration0x13Socket InitNormal state after opening0x17Socket EstablishedConnection successful0x22UDP SocketUDP mode active PHY Link Issues python# Check PHY status phy = w5500.get_phy_status() print(f"Link: {phy['link']}") print(f"Speed: {'100M' if phy['speed_100m'] else '10M'}") print(f"Duplex: {'Full' if phy['full_duplex'] else 'Half'}") Advanced Usage Custom Retry Settings python# Set custom retry parameters w5500._write_reg(0x0019, 0x00, [0x13, 0x88]) # RTR = 500ms w5500._write_reg(0x001B, 0x00, 0x0F) # RCR = 15 retries Force ARP Mode python# Enable Force ARP for problematic networks mr = w5500._read_reg(0x0000, 0x00, 1)[0] w5500._write_reg(0x0000, 0x00, mr | 0x02) # Set FARP bit Multiple Socket Management python# Open multiple sockets status0 = w5500.socket_open(0, 0x01, 8000) # TCP socket 0 status1 = w5500.socket_open(1, 0x02, 8001) # UDP socket 1

for sock in range(8): w5500.socket_close(sock) Technical Specifications

SPI Mode: Mode 0 and Mode 3 supported SPI Frequency: Up to 80MHz (tested at 10MHz) Socket Count: 8 independent hardware sockets Buffer Size: 32KB total (16KB TX + 16KB RX) Protocols: TCP, UDP, IPv4, ICMP, ARP, IGMP, PPPoE PHY: 10/100 Ethernet with auto-negotiation

Development Notes MicroPython Compatibility This driver is specifically designed for MicroPython and includes:

Memory-efficient register access Non-blocking socket operations Proper error handling for embedded systems No dependencies on Python standard library modules not available in MicroPython

Performance Considerations

Use appropriate SPI frequencies (10-33MHz recommended) Implement proper socket cleanup to prevent resource leaks Monitor PHY status for link state changes Use Force ARP mode only when necessary (increases network traffic)

Contributing When contributing to this project:

Test all changes with actual hardware Maintain compatibility with MicroPython constraints Include diagnostic output for debugging Document any new network configuration requirements Test cable disconnect/reconnect scenarios

License This project is provided as-is for educational and industrial automation purposes. Please ensure compliance with your local regulations when using in commercial applications. References

WIZnet W5500 Datasheet Modbus TCP Specification Siemens S7-1500 Modbus Documentation

Author: Wim Deschoenmaeker Hardware: Raspberry Pi Pico W + WIZnet W5500 Application: Industrial automation and PLC communication