W5500-Ethernet-Controller-for-Raspberry-Pi-Pico-W

A comprehensive MicroPython driver and Modbus TCP client for the WIZnet W5500 Ethernet controller, specifically designed for industrial automation and PLC commu

W5500-Ethernet-Controller for Raspberry Pi Pico W

Project Overview

This project delivers a comprehensive MicroPython driver and Modbus TCP client for the WIZnet W5500 Ethernet Controller, enabling reliable communication between the Raspberry Pi Pico W and industrial PLCs (Programmable Logic Controllers) such as the Siemens S7-1500.

It is specifically designed for industrial automation environments, providing features like automatic recovery after cable disconnects, ARP table management, and detailed diagnostic tools.

From an R&D perspective, this project can serve as a valuable reference for:

Future Single Pair Ethernet (SPE) implementations

WIZnet driver improvement and optimization efforts

Key Features

Complete W5500 Driver: Full SPI register control and Ethernet stack integration

Robust Connection Handling: Automatic recovery from cable or network interruptions

Modbus TCP Client: Reliable industrial-grade communication with Siemens PLCs

Connection Diagnostics: Socket debugging, ARP resolution scripts, and improved diagnostic suite

Multi-Socket Management: Up to 8 simultaneous hardware sockets

MicroPython Optimized: Non-blocking operations, memory-efficient register access

Hardware Requirements

Raspberry Pi Pico W

WIZnet W5500 Ethernet Module

SPI Pin Wiring

| W5500 Pin | Pico Pin | Function |

|---|---|---|

| SCK | GP10 | SPI Clock |

| MOSI | GP11 | Master Out |

| MISO | GP12 | Master In |

| CS | GP13 | Chip Select |

| RST | GP15 | Reset |

| VCC | 3V3 | Power Supply |

| GND | GND | Ground |

Quick Start

Basic W5500 Setup

Siemens PLC Communication

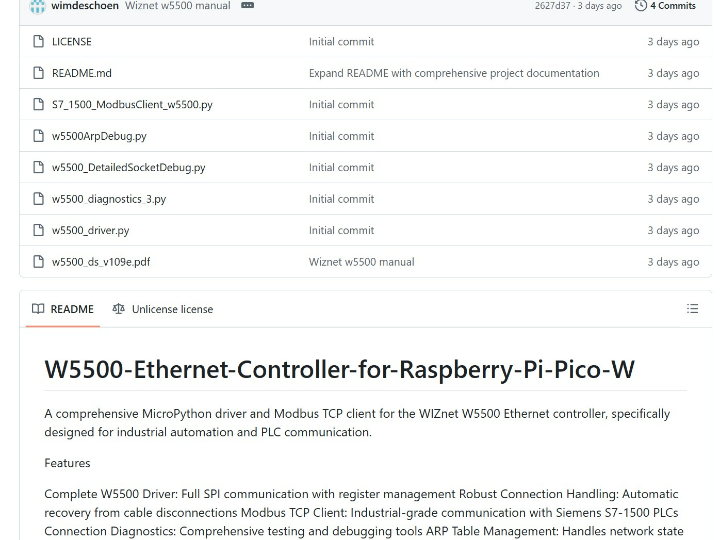

File Structure

Core Components

W5500 Driver (w5500_driver.py)

Full SPI register access (VDM mode)

TCP/UDP socket management

Network configuration utilities

PHY status monitoring

Hardware/software reset

Siemens Modbus Client (siemens_modbus_client.py)

Supported Modbus Functions:

read_holding_registers(start, count) – FC3

write_single_register(address, value) – FC6

write_multiple_registers(start, values) – FC16

read_input_registers(start, count) – FC4

Built-in features: ARP management, auto-reconnect, industrial timeouts

Diagnostic Tools

improved_diagnostics.py → Run complete hardware tests

arp_debug_script.py → Clear ARP tables and fix link issues

simple_reset_test.py → Quick connectivity test

detailed_socket_debug.py → Monitor socket states

Advanced Usage

Custom Retry Settings

Force ARP Mode

Multiple Socket Management

Technical Specifications

SPI Modes: 0 & 3

SPI Frequency: Up to 80 MHz (tested at 10 MHz)

Socket Count: 8 independent hardware sockets

Buffer Size: 32KB (16KB TX + 16KB RX)

Protocols: TCP, UDP, IPv4, ICMP, ARP, IGMP, PPPoE

PHY: 10/100 Ethernet with auto-negotiation

Industrial Relevance & Future Outlook

Validates WIZnet W5500 as a robust solution for industrial automation and PLC communication

Provides open-source reference code for system integrators and engineers

Offers R&D teams valuable insights for:

Enhancing WIZnet’s driver ecosystem

Exploring Single Pair Ethernet (SPE) adoption

Building more resilient industrial networking stacks

Contributing

Test with real hardware

Ensure MicroPython compatibility

Include diagnostics for debugging

Document new features

Validate cable disconnect/reconnect scenarios

References

Siemens S7-1500 Modbus Documentation

Author: Wim Deschoenmaeker

Hardware: Raspberry Pi Pico W + WIZnet W5500

Application: Industrial automation & PLC communication