Design of Meat Product Safety Information Chain Traceability System Based on UHF RFID

This paper presents a meat product safety traceability system using UHF RFID technology to enhance the transparency and efficiency of the meat supply chain.

Ensuring the safety and traceability of meat products is a critical concern for the food industry. This study proposes a comprehensive system for tracking and managing meat products throughout their entire lifecycle, from breeding to sale, using advanced RFID technology.

Key Components and Findings:

UHF RFID Technology: The system employs ultra-high frequency (UHF) RFID technology, which offers several advantages over traditional methods, such as increased read range and speed, ability to handle multiple tags, and resilience to harsh environmental conditions. UHF RFID allows for efficient identification and tracking of meat products at various stages, ensuring that each item can be traced back to its origin.

System Architecture:

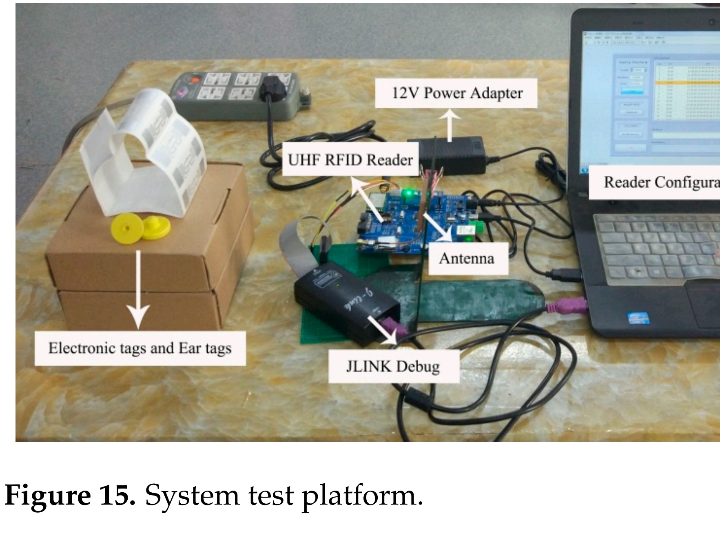

- Hardware Design: The hardware consists of a UHF RFID reader powered by a STM32F103RET6 microcontroller, coupled with a MagicRF M100 chip for RF transceiver functionality. Additional components include power amplifiers and filters for improved performance.

- Communication Interfaces: The system supports multiple communication methods, including USB, LoRa, RS485, and RJ45 Ethernet, with the WIZnet W5500 chip facilitating Ethernet communication. This flexibility ensures compatibility with various network setups and enhances data transmission efficiency.

- Power Management: A robust power supply design ensures stable operation of the RFID reader and other components, with the ability to adjust radiofrequency output power as needed.

Traceability System: The platform integrates various modules to manage different stages of the supply chain:

- Breeding Management: RFID ear tags are used to collect data on livestock, including breed information, health records, and feeding schedules.

- Slaughter and Processing: Electronic tags transition to paper labels for processed meat, with information updated at each step.

- Logistics and Distribution: The system tracks logistics details such as transit temperature and shipment status, ensuring product integrity during transportation.

- Sales Management: Final products are labeled with QR codes or barcodes, providing consumers with detailed traceability information at the point of sale.

Data Management: A centralized database, built using MySQL and accessible via a LabVIEW interface, stores all traceability data. The platform enables stakeholders to perform detailed queries and obtain real-time insights into the supply chain.

Anti-Collision Algorithm: The system implements an advanced Q-algorithm for multi-label reading, optimizing the recognition rate and reducing errors associated with label collision. This ensures accurate data collection even in environments with high tag density.

Applications and Benefits:

- Transparency and Safety: By providing detailed information on each stage of production, the system enhances consumer confidence and helps regulatory authorities monitor food safety standards.

- Efficiency: Automation of data collection and management streamlines operations, reducing the potential for human error and improving overall efficiency.

- Scalability: The modular design allows for easy adaptation to different scales of operation, making it suitable for both small-scale producers and large industrial facilities.

Hashtags: #MeatSafety #RFID #SupplyChain #Traceability #FoodSafety #WIZnet #UHF #IoT Categories: Food Safety, Supply Chain Management, RFID Technology, Internet of Things (IoT), Agriculture

Publish Date: March 23, 2023