Cotton Gin Stand Machine-Vision Inspection and Removal System for Plastic Contamination:

This paper presents a machine-vision system for detecting and removing plastic contamination in cotton gins using advanced hardware and software integration.

Plastic contamination in cotton lint is a significant challenge for the U.S. cotton industry, particularly from plastic wraps used in harvesting. This study introduces a machine-vision inspection and removal system designed to address this issue, focusing on the integration of innovative technologies for effective detection and removal of plastic contaminants in cotton processing.

Key components and findings include:

Machine-Vision System: Utilizes low-cost color cameras and machine-learning algorithms to detect plastic contaminants on the gin stand feeder apron, where the cotton stream is most dispersed.

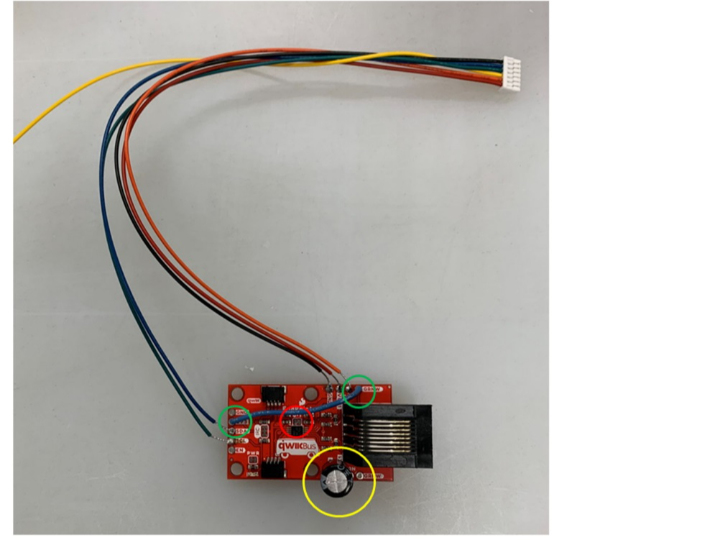

Hand Intrusion Detection (HID) System: Developed to prevent false positives during the calibration process, which occur when gin personnel inadvertently interrupt the camera view. This system uses LiDAR technology to detect hand intrusion events and filter out false positives.

WIZnet W5500 Ethernet Module: Incorporated for robust data communication between the machine-vision system and the control server. The W5500 module ensures reliable and efficient data transfer, crucial for real-time processing and decision-making.

Auto-Calibration Algorithm: An adaptive learning component that refines the system's ability to differentiate between cotton and plastic, minimizing false positives and enhancing detection accuracy.

System Architecture: Includes a network of 30–50 Linux-based ARM computers running machine-vision software developed in C++. The system's architecture is designed for scalability and ease of integration in existing cotton gin operations.

Testing and Implementation: The system was tested in commercial cotton gin facilities, demonstrating significant improvements in plastic detection and removal, reducing contamination and improving cotton quality.

The study highlights the economic impact of plastic contamination, which has led to significant financial losses for the U.S. cotton industry. By implementing this machine-vision system, the industry can enhance cotton quality, reduce contamination, and regain its competitive advantage in the global market.

Hashtags: #MachineVision #CottonGin #PlasticContamination #WIZnet #W5500 #LiDAR #Automation #AgriTech Categories: Agriculture, Automation, Machine Vision, Data Communication, Industrial Technology

Publish Date: December 22, 2023