Real-Time CNC Control with Remora-Core [remora-cnc]

Open-source C++ firmware ‘remora‑core’ by remora‑cnc: real‑time control core for custom CNC setups using STM32 or similar microcontrollers.

Project Introduction: Real-Time CNC Control with Remora Core

1. Introduction

CNC control is a core technology in manufacturing and industrial automation.

This project demonstrates how to implement a real-time CNC control environment using an STM32 microcontroller and Remora Core firmware in an open-source approach.

2. From NC to CNC

Originally, Numerical Control (NC) machines in the 1940s–50s operated from punched tape instructions, moving tools automatically without manual levers. However, modifying or reprogramming was inconvenient.

With the rise of computers, NC evolved into Computer Numerical Control (CNC). CAD/CAM software generates G-code programs that CNC controllers interpret, enabling machines to perform precise and complex operations. This evolution dramatically improved productivity, accuracy, and flexibility.

3. CNC Basics

CNC machines move tools across X, Y, and Z axes to cut or shape a workpiece.

Stepper or servo motors drive the axes precisely, while the controller interprets G-code commands to generate pulses and manage motion.

In short: “Computer interprets → Tool moves → Material is shaped.”

4. Project Overview: Remora Core

Remora is an open-source CNC firmware enabling real-time control on low-cost STM32 MCUs.

It originated as a complement to LinuxCNC for PC-based control, with two goals:

Deterministic real-time behavior

Modular design

5. Key Differentiator: Abstraction Layer

The major innovation in Remora Core is the introduction of an abstraction layer.

Traditional approach: Previous Remora firmware implementations were board-specific, with step generators, PWM drivers, and sensors hardcoded for each MCU. This made porting or extending hardware difficult.

Core approach: Remora Core separates what to control from how to control it.

Shared abstract interfaces handle generic logic.

Hardware-specific drivers implement the details.

Benefits:

Reusability – Core logic can be reused across multiple MCU families.

Flexibility – JSON configuration allows modules to be reassigned to threads without recompiling.

Maintainability – Hardware changes only require updating the driver layer, not the Core.

Thus, Remora Core evolves from “board-specific firmware” into a platform with scalability and portability.

6. Remora Core Structure

At the heart of the project is remora.cpp, which orchestrates the system lifecycle:

Loads JSON configuration and creates modules.

Registers modules to real-time threads.

Initializes interrupts and communication interfaces.

Runs a main loop for host communication and status management.

Pseudocode overview of the core logic:

This structure provides clear control of the entire firmware lifecycle:

Configuration → Module Creation → Threads & Interrupts → Main Loop.

7. Achievements, Limitations, and Future Work

Achievements

Interrupt-driven design ensures deterministic execution.

Modular structure scales from small DIY CNC setups to multi-axis machinery.

Active GitHub development ensures ongoing improvements.

Limitations

Lack of formal performance benchmarks and comprehensive build guides.

Broader MCU support and richer documentation are needed.

Future Potential

Related projects like Remora-NVEM demonstrated Ethernet-based CNC control using a WIZnet W5500 module, pointing toward distributed, network-enabled CNC systems.

7.1 SPE Applicability Check

Existing CNC Communication (by use case)

Traditional → RS-232 / RS-485

Stable but low bandwidth; used mainly for G-code transfer and status reporting.

Real-time bus → CAN / CANopen

Reliable for motor drivers and sensors, but bandwidth limited (~1 Mbps).

High-speed precision → EtherCAT / Profinet / Modbus-TCP

Industrial Ethernet standards, dominant for multi-axis precision CNC.

Wireless (auxiliary) → Wi-Fi, Bluetooth

Rarely used for core control; mostly for monitoring or sensors.

SPE Evaluation

Advantages

Single pair cable delivers data + power (PoDL).

Higher bandwidth than RS-485/CAN, direct Ethernet compatibility.

Simplified cabling, reduced installation and maintenance costs.

Limitations

Lacks proven hard real-time determinism compared to EtherCAT/Profinet.

Currently more suitable for sensors and I/O networks than core axis control.

✅ Conclusion

SPE can effectively replace RS-485 or CAN for sensor and peripheral networks, simplifying CNC wiring.

However, for hard real-time axis control, EtherCAT/Profinet remain superior, while SPE is better viewed as a complementary technology with future growth potential.

8. Conclusion

Remora Core is a next-generation CNC control platform built on an abstraction layer.

It combines low-cost MCU hardware with real-time capability, scalability, and open-source flexibility.

With Ethernet extensions (e.g., W5500) and emerging technologies such as SPE, it shows potential for broader adoption in smart manufacturing, automation research, and educational CNC systems.

Author’s Other Repositories & Project Tendencies

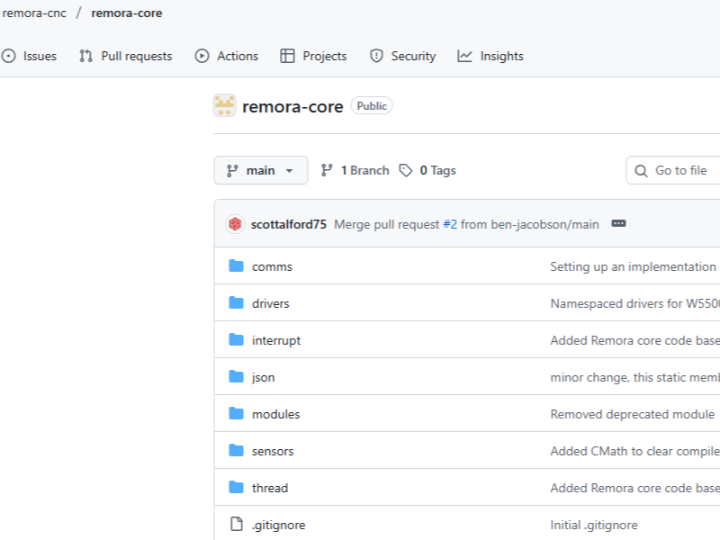

The remora-cnc GitHub organization currently manages two public repositories:

remora-core (C++, GPL-3.0) – actively maintained, last update: August 23, 2025.

Remora-STM32H7xx-PIO (C language) – last update: August 10, 2025.

This activity highlights an ongoing focus on STM32-based CNC platforms with modular firmware design, real-time determinism, and GPL-licensed open-source development.

Related Maker Project

A related project on WIZnet Maker is titled:

“Remora – Ethernet NVEM CNC Board / Remora-NVEM”

Extends Remora firmware to support Ethernet-based CNC control.

Uses the WIZnet W5500 interface on an STM32F207 NVEM board.

Serves as a proof-of-concept for integrating networked CNC operations into the Remora framework.

References

GitHub – Remora-Core repository (C++, GPL-3.0)

https://github.com/scottalford75/Remora

GitHub – Remora-STM32H7xx-PIO (C firmware)

https://github.com/scottalford75/Remora-STM32H7xx-PIO

WIZnet Maker – Remora STM32F4xx PIO Port project

https://maker.wiznet.io/matthew/projects/remora-stm32f4xx-pio-port/

WIZnet Maker – Remora NVEM Ethernet CNC project

https://maker.wiznet.io/matthew/projects/remora-ethernet-nvem-cnc-board/

CNC Control background – LinuxCNC documentation (Remora plugin context)

http://linuxcnc.org/