STM32-Serial-to-Ethernet-Converter

An STM32F103 + W5500–based UART-to-TCP bridge that acts like an open-source USR-TCP232 module, enabling transparent Serial ⇄ Ethernet communication.

👤AUTHOR

vorun

An embedded systems developer focused on STM32, low-level peripheral programming, bare-metal drivers, and lightweight network stacks.

He builds educational microcontroller projects, custom bootloaders, and minimal network gateways using pure C and open hardware tools.

🔗 GitHub: https://github.com/vorun/STM32-Serial-to-Ethernet-Converter

🎯PROJECT DESCRIPTION

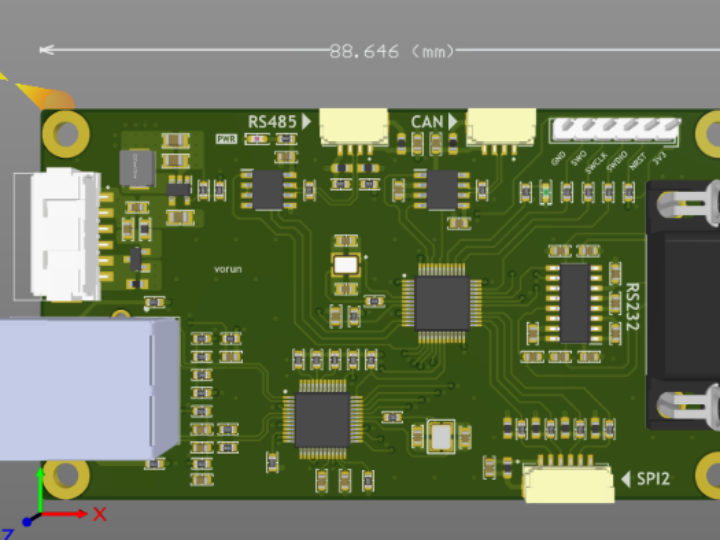

This project implements a Serial-to-Ethernet Converter that bridges RS232, RS485, and CAN communication to Ethernet TCP using:

- STM32F103C8T6 (Blue Pill)

- WIZnet W5500 (Hardware TCP/IP Ethernet Controller)

The device works as a transparent Serial ⇄ TCP gateway—similar to industrial devices like USR-TCP232—allowing legacy serial devices to be accessed remotely over a network.

Compared to software-based ENC28J60 designs, the W5500 drastically improves performance, reliability, and reduces MCU load by handling TCP/IP in hardware.

🧩COMPONENTS

🧠 Hardware

- STM32F103C8T6 development board

- RS232 (5V level, USART1)

- RS485 (3.3V, USART2)

- CAN (5V, CAN peripheral)

- WIZnet W5500 Ethernet Controller (SPI1)

🧰 SYSTEM OVERVIEW

[TCP Client: PC / Server / Application]

↑ ↓

Ethernet (TCP/IP)

↑

WIZnet W5500 Ethernet

↑ SPI

STM32F103 MCU

↑ UART

Serial Device (Sensor/MCU)

The STM32 simply reads/writes socket buffers via SPI,

while the W5500 handles TCP/IP packetization and link management.

This ensures:

- deterministic latency

- low CPU overhead

- stable operation under heavy traffic

✔ KEY FEATURES

🔹 Multi-Protocol Serial Support

- RS232 (DB-9)

- RS485 (3.3V differential)

- CAN (5V transceiver)

All mapped to Ethernet TCP.

🔹 Transparent Serial Bridge

Data passes between TCP client and serial port without modification:

- TCP → UART

- UART → TCP

This makes it compatible with:

- PLCs

- sensors

- CNC controllers

- industrial monitors

- legacy devices

🧪USE CASES

- Industrial PLC Ethernet integration

- Remote serial port server

- SCADA / HMI communication

- CNC machine networking

- CAN-bus monitoring over LAN

- Legacy equipment modernization

📌 This UCC focuses on the hardware capabilities of the design. The original project provides hardware resources only—no official firmware or ready-to-use software stack is included. Users are expected to build their own S2E firmware or integrate custom communication protocols using STM32 and the W5500.