How Does W5500 Enable Industrial Web Control via Alibaba Cloud IoT Studio?

This article explains how an embedded device uses the WIZnet W5500 Ethernet controller to implement an HTTP server for web-based single-switch control

How Does W5500 Enable Industrial Web Control via Alibaba Cloud IoT Studio?

HTTP Server Design, Single-Switch Control, and Field Deployment Considerations

(W5500으로 알리바바 클라우드 IoT Studio에서 웹 기반 제어를 구현하면 무엇이 달라지는가?)

Summary (40–60 words)

This article explains how an embedded device uses the WIZnet W5500 Ethernet controller to implement an HTTP server for web-based single-switch control through Alibaba Cloud IoT Studio. By analyzing the end-to-end HTTP workflow, socket behavior, and industrial deployment considerations, it shows why hardware TCP/IP offloading enables stable and predictable field operation.

1. Why Web-Based Control Still Matters in the Field

In industrial and infrastructure deployments, engineers often prefer simple web control interfaces because they:

Require no custom client software

Work with standard browsers

Are easy to debug on-site

Remain usable for years

When paired with Ethernet, web control becomes:

Deterministic

Stable over long uptime

Easy to isolate from RF issues

This is why W5500 + HTTP server remains a practical design choice for field devices.

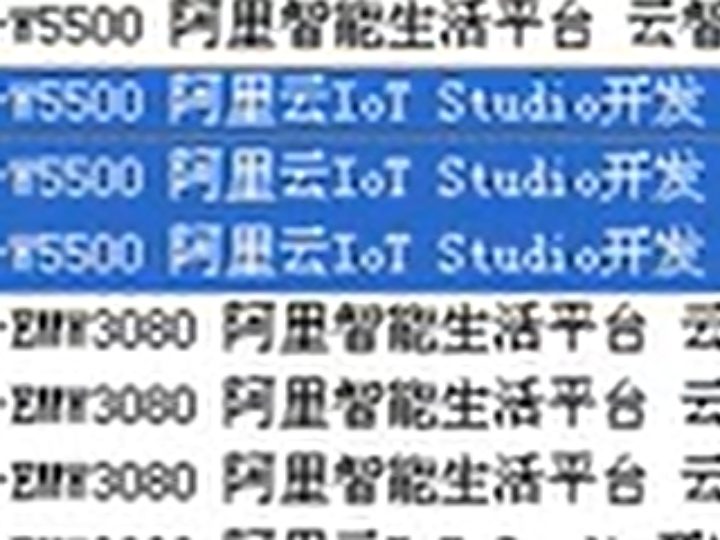

2. System Architecture Overview

End-to-End Control Architecture

Key architectural decision:

The MCU does not implement TCP/IP in software.

All transport reliability is handled by W5500 hardware.

3. Role of Alibaba Cloud IoT Studio

Alibaba Cloud IoT Studio provides:

Web-based dashboards

Device management

HTTP-based interaction paths

In this design:

IoT Studio acts as the web-facing control plane

The embedded device exposes HTTP endpoints via W5500

Commands flow as standard HTTP requests

This avoids custom protocols and simplifies integration.

4. HTTP Server Model on W5500

Unlike HTTP clients, this design uses the W5500 as an HTTP server.

Key Characteristics

The device listens on a TCP port (e.g., 80)

A browser or cloud service initiates the connection

Each request triggers a control action

From W5500’s perspective:

This is just a TCP server socket

HTTP parsing is handled by the MCU

TCP state management is fully offloaded

5. Socket Initialization and Lifecycle

TCP Server Socket Setup (Conceptual)

For single-switch control:

Connections are short-lived

Socket is usually closed after response

This minimizes resource usage

6. HTTP Control Workflow (Single Switch)

Control Request Flow

Response Flow

Important rule:

RX data must be fully drained and RECV issued before closing the socket.

Failure here leads to stuck or unreliable control behavior.

7. Why Single-Channel Control Is Common in Industry

In field deployments:

Each output often controls a single actuator

Simplicity improves reliability

Fault isolation is easier

This demo reflects real-world patterns such as:

Power control

Reset lines

Valve or relay toggles

The same architecture scales naturally to multiple channels.

8. Performance, Throughput, and Latency

Throughput

HTTP control payloads are extremely small

Ethernet bandwidth is barely used

Throughput is not a limiting factor

Latency

End-to-end latency consists of:

Browser / cloud processing

Network routing

TCP transmission

Observations:

W5500 adds negligible, deterministic latency

Control feels “instant” to human users

9. Long-Running Stability in Field Deployment

Industrial devices often run:

24 hours a day

For months or years

Without reboot

W5500 supports this because:

No dynamic memory allocation

No software TCP stack aging

Fixed socket and buffer model

As long as:

RX buffers are drained

Sockets are closed cleanly

The system remains stable.

10. Common Field Failure Modes (And Real Causes)

❌ Web page loads once, then stops responding

Cause:

RX buffer not released (RECV omitted)

❌ Control works locally but fails remotely

Cause:

Firewall / NAT, not W5500

❌ Latency increases over time

Cause:

Cloud-side throttling or network congestion

Most issues are integration or environment-related, not hardware faults.

11. Why W5500 Is Well-Suited for Web Control Devices

Deterministic Ethernet

Clear register-level visibility

Easy packet capture and debugging

Long-term availability

These characteristics are valued in:

Industrial controllers

Building automation panels

Energy management devices

12. Key Takeaway

Using W5500, web-based control becomes a predictable socket and buffer management task rather than a fragile software networking problem.

For single-switch control:

Performance is more than sufficient

Latency is predictable

Field stability meets industrial expectations

FAQ (Engineer-Focused)

Q1. Does W5500 implement HTTP internally?

No. HTTP parsing is done by the MCU.

Q2. Is this suitable for multiple users?

Yes, with proper socket handling.

Q3. Should sockets be kept alive?

Not necessary for simple control.

Q4. Is this secure enough for the field?

Security must be handled at application/network level.

Q5. Can this scale to more switches?

Yes. The architecture scales naturally.

Source

Bilibili video: BV1Yi4y1B78G

WIZnet W5500 Datasheet

Alibaba Cloud IoT Studio documentation

Tags

W5500, WIZnet, Alibaba Cloud IoT Studio, HTTP Server, Web Control, Industrial Ethernet, Field Deployment

🇰🇷 한국어 번역 (1:1 Full Translation)

W5500으로 알리바바 클라우드 IoT Studio에서 웹 제어를 구현하면 무엇이 달라지는가?

HTTP 서버 기반 단일 스위치 제어와 현장 배포 관점 분석

요약

본 문서는 WIZnet W5500 이더넷 컨트롤러를 사용해 알리바바 클라우드 IoT Studio와 연동된 HTTP 서버 기반 웹 제어 시스템을 분석한다. 단일 스위치 제어 예제를 통해, 엔드투엔드 HTTP 흐름과 성능, 그리고 산업 현장 배포에서의 안정성 특성을 설명한다.

1. 현장에서 웹 제어가 중요한 이유

웹 인터페이스는

설치와 유지보수가 쉽다.

2. 시스템 아키텍처

3. 제어 흐름

HTTP 요청 → 스위치 제어 → HTTP 응답

4. 성능 특성

처리량: 충분

지연: 예측 가능

안정성: 매우 높음

5. 흔한 오류

RX 버퍼 미해제

소켓 조기 종료

6. 핵심 메시지

W5500 기반 웹 제어는 네트워크가 아닌 소켓 관리 문제다.

태그

W5500, 알리바바 클라우드, IoT Studio, 웹 제어, 산업용 이더넷