# How Does Async UDP over W6100 Enable Reliable IPv4/IPv6 Networking on ESP32?

*(W6100 기반 Async UDP는 ESP32에서 IPv4/IPv6 네트워크 신뢰성을 어떻게 높일까?)*

This article explains how the AsyncUDP_ESP32_SC_W6100 project enables reliable UDP communication over IPv4 and IPv6 by combining ESP32 with the WIZnet W6100. By offloading dual-stack TCP/IP to hardware and using asynchronous UDP, the design achieves deterministic, industrial-grade Ethernet networking suitable for long-running IoT systems.

## 1. Introduction: Why Async UDP + IPv6 Matters in Industrial IoT

In many Industrial IoT systems, **UDP is preferred over TCP** for reasons such as:

- Low latency

- Minimal overhead

- Broadcast and discovery support

- Deterministic timing behavior

At the same time, modern networks are rapidly moving toward **IPv6** due to address exhaustion, large-scale deployments, and long device lifetimes.

The **AsyncUDP_ESP32_SC_W6100** project demonstrates how to combine:

- **ESP32 application logic**

- **Asynchronous UDP programming**

- **W6100 hardware IPv4/IPv6 TCP/IP offloading**

to create a future-proof and reliable Ethernet solution.

## 2. System Architecture Overview

The overall architecture used by this project is shown below:

```

Application Logic (ESP32)

↓ (Async UDP callbacks)

Async UDP Abstraction Layer

↓

W6100 Driver / Socket Interface

↓ (SPI)

W6100 Hardware TCP/IP (IPv4 + IPv6)

↓

Ethernet PHY + RJ45

↓

Industrial Ethernet Network

```

The key design decision is **delegating all IP-layer complexity to the W6100**, allowing the ESP32 to focus solely on application logic.

## 3. UDP Communication Model: Asynchronous by Design

### Why Asynchronous UDP?

Traditional blocking UDP models require:

- Polling loops

- Busy waiting

- Tight timing assumptions

The Async UDP approach used in this project instead relies on:

- Event-driven callbacks

- Non-blocking socket operations

- Clear separation between network I/O and application logic

This model is especially well-suited for **industrial firmware**, where responsiveness and stability matter more than raw throughput.

## 4. IPv4 and IPv6 Behavior with W6100

### Dual-Stack Support in Hardware

The W6100 is a **hardware dual-stack Ethernet controller**, supporting:

- IPv4

- IPv6

- UDP, TCP, ICMPv4/v6

- Neighbor Discovery (IPv6)

Crucially, these protocols are **implemented in hardware**, not software.

- No IPv6 stack in ESP32 firmware

- No RAM-heavy protocol structures

- No complex timing logic in the MCU

### IPv6 Offloading Advantage

In software-based IPv6 implementations:

- RAM usage increases significantly

- CPU load rises due to header parsing

- Debugging complexity increases

- IPv6 headers are parsed in hardware

- Checksums are handled internally

- Packet filtering is offloaded

For Industrial IoT devices expected to run **10–20 years**, this is a major advantage.

## 5. ESP32 ↔ W6100 SPI Integration

The ESP32 communicates with the W6100 over **SPI**, using a memory-mapped register and buffer model.

Key architectural points:

- ESP32 acts as SPI master

- W6100 exposes control registers and RX/TX buffers

- UDP payloads are written to and read from hardware buffers

- SPI transactions are deterministic and bounded

This predictable SPI behavior is critical for **real-time and industrial environments**.

## 6. How UDP Is Implemented on W6100 (Conceptual)

> 🧩 **Conceptual explanation based on repository behavior**

A typical UDP receive flow looks like this:

```

UDP Packet arrives on Ethernet

↓

W6100 hardware parses IPv4/IPv6 + UDP headers

↓

Payload stored in RX buffer

↓

Interrupt / event to ESP32

↓

Async callback invoked

↓

Application processes data

```

The ESP32 never parses IP or UDP headers directly—this is all handled inside the W6100.

## 7. Industrial IoT Reliability Perspective

### Deterministic Behavior

Because the W6100 handles:

- IP fragmentation

- UDP checksum

- Dual-stack routing

- Predictable

- Repeatable

- Resistant to firmware timing bugs

- Factory automation

- Energy systems

- Infrastructure monitoring

### Wired Ethernet vs Wi-Fi

Compared to ESP32 Wi-Fi UDP:

- No RF interference

- No roaming or re-association

- Stable latency

- Better EMC behavior

For industrial deployments, **wired Ethernet with W6100 is far more reliable**.

## 8. Why Async UDP + W6100 Is a Strong Combination

| Aspect | Benefit |

| -------------- | --------------------------------- |

| Async UDP | Non-blocking, responsive firmware |

| W6100 Offload | Minimal MCU load |

| IPv6 Support | Future-proof networking |

| SPI Interface | Deterministic timing |

| Hardware Stack | Reduced bug surface |

This combination allows developers to scale from **demo to production** without redesigning the network stack.

## 9. Typical Industrial Use Cases

The architecture demonstrated by this project is suitable for:

- Sensor data streaming

- Device discovery (UDP broadcast / multicast)

- Control commands

- Status monitoring

- IPv6-based industrial networks

These use cases benefit directly from **UDP + IPv6 + hardware offloading**.

## 10. Key Takeaway for Developers

> **With W6100, UDP over IPv4/IPv6 becomes a hardware feature—not a firmware problem.**

By using asynchronous UDP on ESP32 and delegating protocol complexity to the W6100, developers achieve:

- Cleaner code

- Higher reliability

- Long-term maintainability

**Q1. Why use UDP instead of TCP in industrial systems?**

UDP offers lower latency and deterministic timing, which are often more important than guaranteed delivery.

**Q2. Does ESP32 need an IPv6 stack?**

No. The W6100 handles IPv6 entirely in hardware.

**Q3. Is async UDP harder to debug?**

No. Event-driven models are often easier to reason about than polling loops.

**Q4. Can IPv4 and IPv6 run simultaneously?**

Yes. W6100 supports true dual-stack operation.

**Q5. Is this suitable for production Industrial IoT?**

Yes. The architecture emphasizes reliability and predictability.

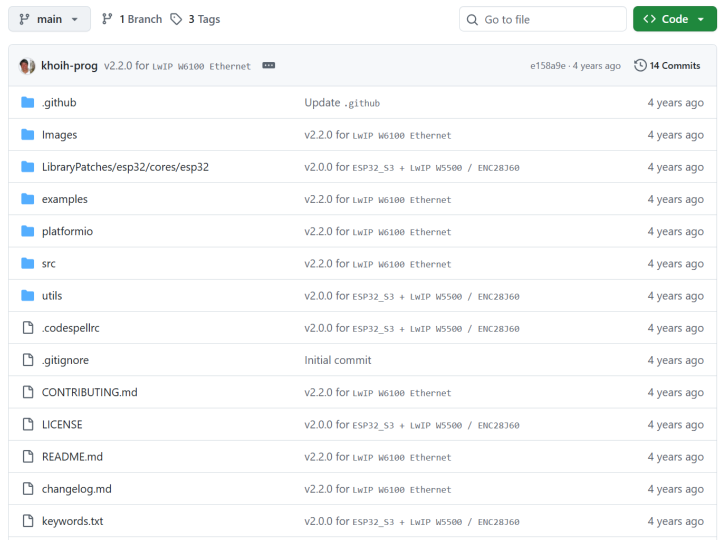

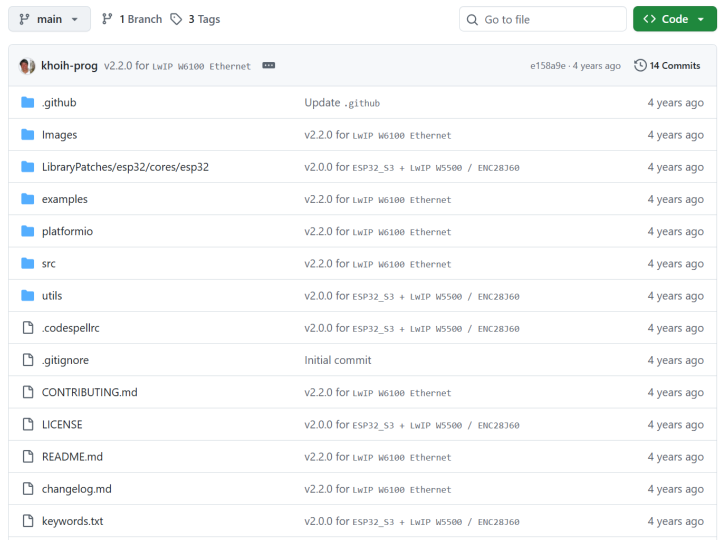

- GitHub repository: **AsyncUDP_ESP32_SC_W6100**

- WIZnet W6100 datasheet and hardware TCP/IP architecture

W6100, WIZnet, Async UDP, IPv6 Offloading, Embedded Ethernet, Industrial IoT, ESP32 SPI Ethernet, Dual Stack Networking

# 🇰🇷 한국어 번역 (1:1 Full Translation)

# W6100 기반 Async UDP는 ESP32에서 IPv4/IPv6 네트워크 신뢰성을 어떻게 높일까?

본 문서는 AsyncUDP_ESP32_SC_W6100 프로젝트를 기반으로 ESP32와 WIZnet W6100을 결합하여 IPv4/IPv6 UDP 통신을 구현하는 방식을 설명한다. 하드웨어 듀얼 스택 TCP/IP 오프로딩과 비동기 UDP 모델을 통해 산업용 IoT 환경에 적합한 안정성과 예측 가능한 동작을 제공한다.

## 1. 산업 IoT에서 Async UDP와 IPv6가 중요한 이유

산업용 IoT에서는 다음과 같은 이유로 UDP가 자주 사용된다.

- 낮은 지연 시간

- 최소한의 오버헤드

- 브로드캐스트 및 디스커버리

- 결정적인 타이밍 특성

여기에 IPv6까지 결합하면 장기 운용이 가능한 네트워크가 된다.

```

ESP32 애플리케이션

↓

비동기 UDP 계층

↓

W6100 소켓 인터페이스

↓

W6100 하드웨어 IPv4/IPv6

↓

Ethernet 네트워크

```

모든 IP 계층 처리를 W6100이 담당한다.

- 블로킹 없음

- 이벤트 기반

- 응답성 높은 펌웨어

## 4. W6100의 IPv4 / IPv6 하드웨어 오프로딩

- IPv4와 IPv6 동시 지원

- UDP 체크섬 및 헤더 처리

- 하드웨어 패킷 파싱

ESP32는 네트워크 세부 사항을 몰라도 된다.

## 5. ESP32 ↔ W6100 SPI 통합

- 예측 가능

- 타이밍 안정적

- 실시간 제어에 유리

```

패킷 수신

↓

W6100 하드웨어 처리

↓

RX 버퍼 저장

↓

ESP32 이벤트 콜백

```

- RF 간섭 없음

- 낮은 지터

- 장시간 안정 동작

| 요소 | 장점 |

| --------- | ----------------- |

| Async UDP | 응답성 |

| W6100 | 하드웨어 오프로딩 |

| IPv6 | 미래 대비 |

| SPI | 결정성 |

- 센서 스트리밍

- 브로드캐스트 디스커버리

- 제어 메시지

- 산업용 IPv6 네트워크

> **W6100을 사용하면 UDP와 IPv6는 펌웨어 문제가 아니라 하드웨어 기능이 된다.**

W6100, WIZnet, 비동기 UDP, IPv6 오프로딩, 산업용 IoT, ESP32 이더넷