[Recuration] Industry 4.0 – Connecting Traditional Hardware to Internet(add Industry 5.0)

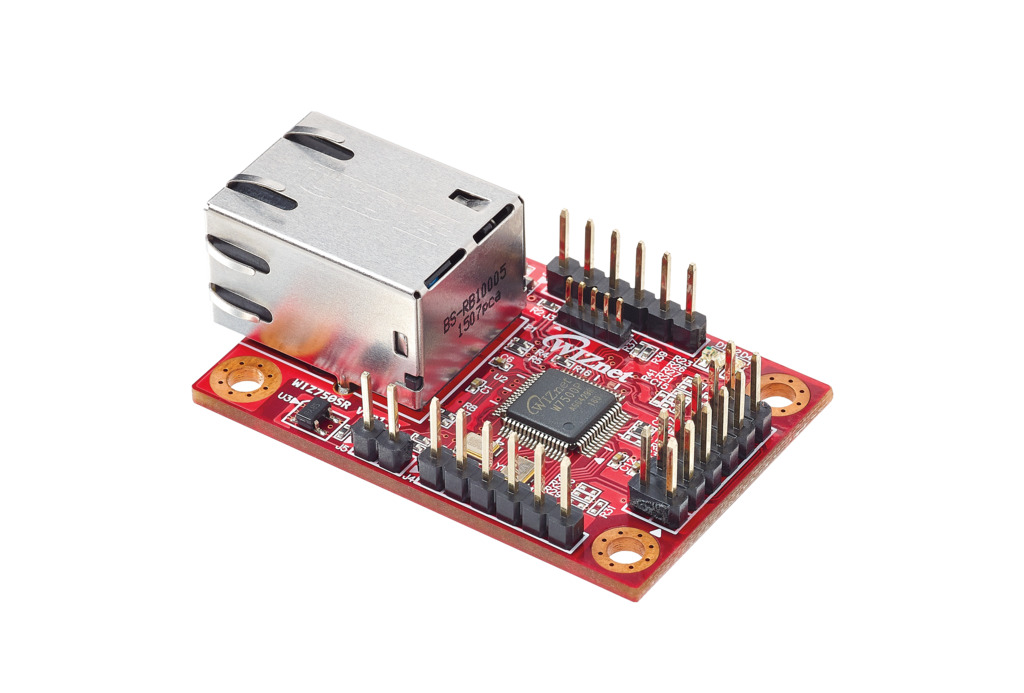

This project is aimed at leveraging use of WIZnet board to connect to industrial meters, appliances, SCADA, and PLCs.

Project Overview: Connecting Industries with WIZnet in the Age of Industry 4.0

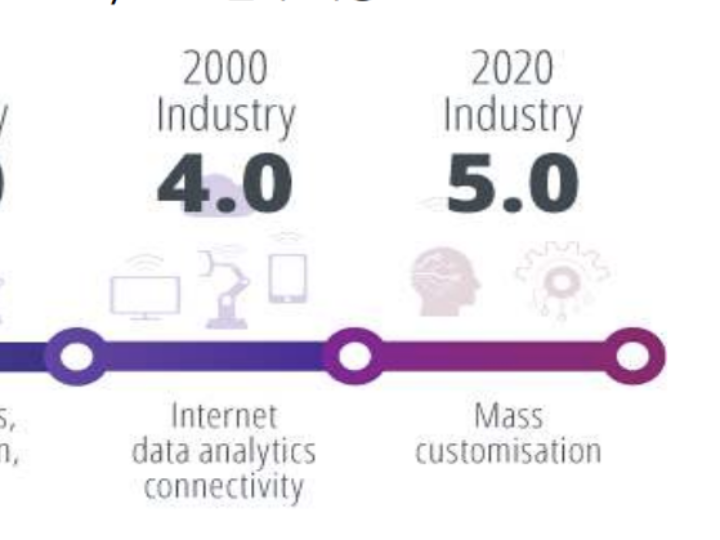

In the ever-evolving landscape of industrial automation and data exchange, Industry 4.0 stands out as the fourth industrial revolution. It's all about connecting machines, sensors, meters, SCADA, and PLCs to the internet, creating a seamless network of smart manufacturing technologies.

Why WIZnet?

WIZnet plays a crucial role in making Industry 4.0 a reality. Here's why it's the go-to choice for connecting industrial devices:

Cost-Effective Integration:

- WIZnet enables seamless integration with existing setups, saving on additional investments.

TCP/IP Connectivity:

- It allows connecting serial communication devices to TCP/IP networks, facilitating internet connectivity effortlessly.

Ease of Setup:

- WIZnet is user-friendly, making configuration a breeze without the need for implementing new protocols.

Compatibility:

- No need for inventing or implementing new protocols; WIZnet easily connects with traditional devices.

Project Steps:

WIZnet Configuration:

- Configured TCP/IP based on router settings and adapted serial communication settings based on the energy meter used.

Connecting Industrial Things:

- Connected the industrial device (in this case, a bulb representing an industrial component) to WIZnet using a serial cable. EVB is used for power supply, although not necessary in the final implementation.

Network Setup:

- Both WIZnet and Orange Pi are connected through a router. Power supply to WIZ750SR is provided by Orange Pi through USB and EVB (optional in the actual setup).

Data Storage and Visualization:

- Set up InfluxDB, Telegraf, and Grafana on Orange Pi to efficiently store and visualize data.

Industry 5.0 Comparison:

As we delve into Industry 4.0, it's worth noting the upcoming trends in Industry 5.0. While Industry 4.0 focuses on connectivity and data exchange, Industry 5.0 emphasizes human-machine collaboration. This marks a shift towards a more human-centric approach, combining the strengths of automation with the creativity and problem-solving skills of humans for a more holistic industrial environment.