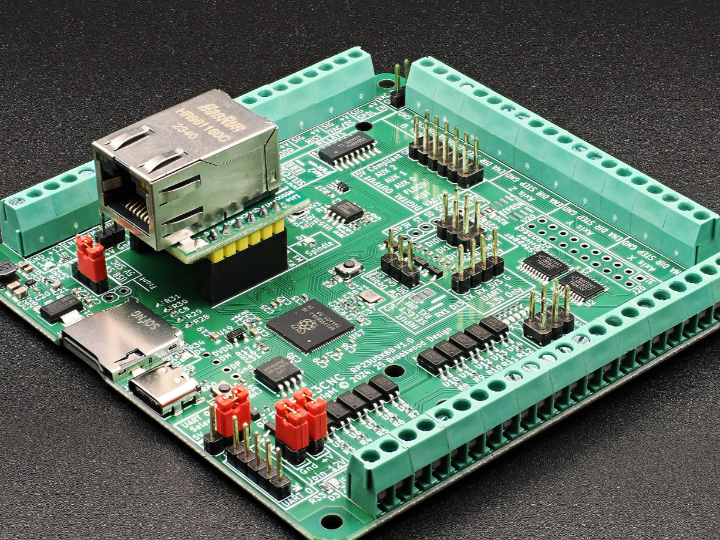

RP23CNC – RP235x-based 5-Axis grblHAL CNC Controller

RP23CNC is a 5-axis CNC controller board powered by the Raspberry Pi RP235x MCU, running the open-source grblHAL firmware.

Key Specifications

5-Axis Control

Step / Direction / Enable outputs (5V compatible)

Limit & Servo error inputs (12V compatible, LED indicators)

Standard Grbl Interface

Cycle Start, Feed Hold, Halt, Safety Door, Probe inputs

LED indicators included

Isolated Inputs

12V isolated input section, joinable to main 12V rail

Output Expansion

Flood, Mist, Aux0–2, Dust Collector

Relay Outputs

5V/12V selectable, up to 100mA drive

Flood, Mist, Aux0–2, Dust Collector, Spindle Enable

Spindle Control

PWM-based speed control

0–10V, 0–5V outputs

Enable / Direction / PWM (5V compatible)

Communication & Storage

2x UARTs

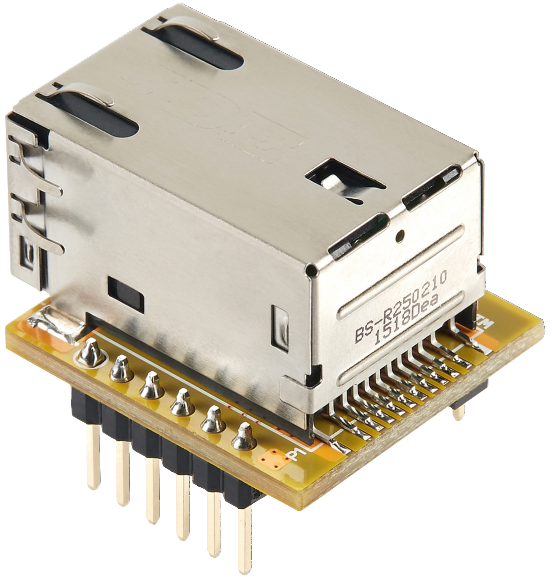

MicroSD card slot

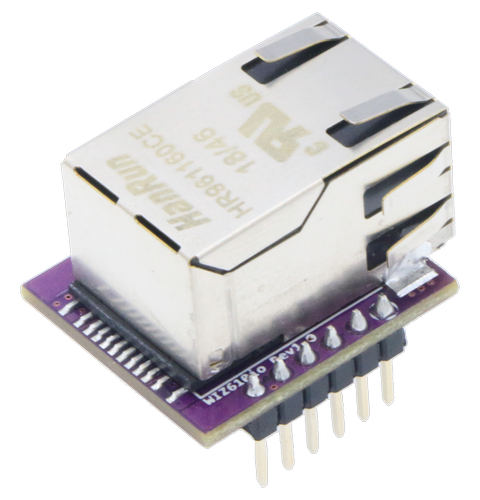

Ethernet via WIZnet module

Power Section

12V main input + isolated input

5V and 3.3V regulators

Role of the WIZnet Chip

Hardware TCP/IP Offloading: RP235x focuses on motion control, while the WIZnet chip handles all TCP/IP networking.

Stable CNC Networking: Enables connection to remote PCs, IoT gateways, or web servers.

Scalability: Beyond local control, the WIZnet module allows network-based CNC + IoT integration projects.

Development History

V0.92 (Feb 2025): grblHAL boot confirmed, 5-axis motion verified, WIZnet Ethernet networking tested.

V0.95 (Mar 2025): Switched to USB-C, improved power efficiency, fixed UART pin mapping.

V1.0 (Apr 2025): Stable production release, available on Tindie.

Project Use Cases

The RP23CNC is not just a controller board – it’s a flexible platform that makers can adapt to their own projects:

Desktop CNC Machines

Build small CNC machines for wood or acrylic cutting

Control via web UI without a dedicated PC

IoT-enabled CNC Monitoring

Stream real-time CNC job status through the WIZnet module

Remote monitoring and emergency stop control

Educational CNC/Robotics Platform

Teach students G-code and motion control with grblHAL

Manage multiple devices over the network for hands-on learning

Custom Automation Equipment

Adapt for laser cutters, pick-and-place systems, or 3D printer conversions

Use digital outputs/relays to drive pumps, motors, or dust collectors

Remote CNC Farm Operation

Connect multiple CNCs via WIZnet networking

Centralized management from a server/cloud → small-scale smart manufacturing

Summary

RP235x MCU → Precise motion control

WIZnet Ethernet → Reliable network connectivity

grblHAL Support → Large open-source ecosystem

👉 The RP23CNC offers makers, researchers, and educators an affordable yet expandable CNC controller board that bridges motion control and networked automation.