ESP32-Actuator-Controller

An ESP32-S3 and W5500-powered hardware project providing a compact 20-channel actuator controller designed for reliable industrial Ethernet.

A Hardware-Focused Look at an Ethernet-Controlled Industrial I/O Board

Wired Ethernet remains a reliable and interference-resistant communication method for industrial control systems.

This article examines a publicly shared hardware project that integrates the ESP32-S3 microcontroller and the WIZnet W5500 Ethernet controller to build a 20-channel actuator controller.

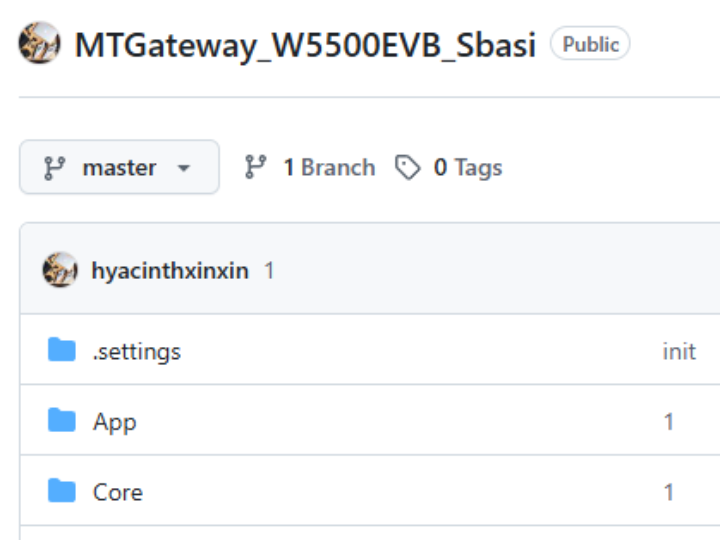

Although the repository focuses on the hardware design (schematic/PCB) rather than firmware, the comprehensive schematic provides a clear view of how a network-controlled industrial output board is architected.

1. Overview

The board integrates four major functional blocks into a single PCB:

- ESP32-S3 – main controller

- WIZnet W5500 – wired Ethernet interface

- 24-V power input stage – industrial-grade power handling

- 20 MOSFET-based SSR outputs – for controlling external loads

Together, these blocks form a network-enabled multi-channel actuator/relay controller suitable for automation and distributed I/O applications.

2. Power Stage – Designed for Industrial 24-V Systems

The schematic (Page 1) shows that the board is powered by a 24-V DC input, a common standard in factory automation.

The power circuitry includes:

- Reverse-polarity protection

- TVS diode protection

- High-current fuse

- 24 V → 5 V buck converter (LMR51430)

- 5 V → 3.3 V LDO regulator (LD39200)

This topology ensures stable operation of the ESP32-S3 and W5500 in demanding environments.

3. Main MCU – ESP32-S3

The board uses the ESP32-S3-MINI-1 module as the primary processor and communication controller.

Key components include:

- USB-C connector for programming

- ESD protection

- Boot and reset circuitry

- Access to SPI/GPIO pins

The ESP32 manages network commands, executes control logic, and drives the output channels.

4. Networking – WIZnet W5500 Ethernet Controller

One of the most notable design choices is the integration of the WIZnet W5500 hardwired TCP/IP controller (Page 3), despite the ESP32 having built-in Wi-Fi.

This configuration strongly suggests a focus on reliability in industrial environments:

- Stability in Harsh Conditions: In factories or areas with heavy metal shielding, wireless signals can be unstable or blocked. The W5500 likely ensures consistent connection where Wi-Fi might fail.

- Plug-and-Play Simplicity: A wired Ethernet approach eliminates the need for SSID/password configuration, allowing the device to communicate immediately upon plugging in the LAN cable.

By offloading network traffic processing to the W5500, the board ensures deterministic Ethernet behavior—critical for automation tasks.

5. Signal Buffering – 20-Channel Level Isolation

Between the ESP32 and the SSR outputs, the design includes five SN74LV4T125 buffer ICs.

These devices:

- Protect ESP32 GPIO pins

- Provide stable logic levels

- Improve noise resistance

- Deliver 20 independent buffered output signals

This stage is essential for reliable multi-channel actuation.

6. Output Stage – 20 MOSFET SSR Channels

The output stage (Page 5) consists of 20 OMRON G3VM-61BR2 MOSFET solid-state relays (SSRs).

Based on the 24V power architecture and SSR specifications, this board is evidently designed to drive 24V industrial loads. Users could connect devices such as:

- 12V/24V DC Motors (for conveyor belts or fans)

- Solenoid Valves (for pneumatic or hydraulic control)

- Industrial Relays & Contactors

- Warning Lights or Tower Lamps

Each channel provides clean ON/OFF switching without mechanical relay wear, featuring a flyback diode for inductive load protection and an LED indicator for visual diagnostics.

7. Output Protection and Indicators

From the schematic alone, the purpose of the hardware is clear. The combination of a 24V supply, 20 SSR channels, and Wired Ethernet indicates that this is a remote I/O module designed to control actuators through a network.

Typical use cases likely include automation equipment control, distributed industrial I/O, or network-controlled relay banks.

8. What This Board Represents

Analyzing the schematic reveals a clear design philosophy: this board acts as a robust gateway between digital networks and physical machinery.

By combining a 24V industrial power architecture with the reliability of W5500 Ethernet, the hardware is evidently designed to serve as a Remote I/O Module. It bridges the gap between software commands (TCP/UDP) and high-power physical actions (20 SSR channels).

Potential Use Cases: Based on the hardware specifications, this board is ideal for:

- Smart Factory Automation: Controlling conveyor belts or sorting mechanisms.

- Fluid Control Systems: Managing banks of solenoid valves for hydraulic or pneumatic systems.

- Building Management: Centralized control of lighting or HVAC relays.

In essence, it is an Ethernet-enabled 24V Output Controller that leverages the ESP32 for logic and the W5500 for stable, always-on connectivity.

This project showcases a fully integrated ESP32-S3 + W5500 20-channel actuator controller, capable of driving 24-V loads over a wired Ethernet connection.

The schematic highlights industrial-grade power handling, reliable network communication, buffered logic control, and MOSFET-based outputs—making the design a strong reference for embedded and automation engineers.